In the ever-evolving world of personalized printing, brand-new modern technologies remain to emerge, offering cutting-edge remedies for services, hobbyists, and creators alike. Amongst these improvements, DTF (Direct to Film) printing has taken spotlight, reinventing exactly how we come close to clothing decoration and past. Whether you're a small company owner aiming to broaden your item offerings or a DIY lover eager to experiment, DTF Transfers offer a functional, top notch option that's worth discovering. In this extensive overview, we'll dive into the basics of Direct to Film, check out the specifics of Direct to Film Transfers, and clarified the interesting possibility of UV DTF Transfers

What is DTF Printing?

DTF, short for Direct to Film, is a sophisticated printing method that permits users to move vibrant, in-depth layouts onto a range of surface areas, most frequently textiles like cotton, polyester, and blends. Unlike conventional approaches such as screen printing or warm transfer plastic (HTV), DTF Transfers streamline the process by publishing layouts onto a special film, which is then moved to the substratum using warm and stress. The outcome? Durable, full-color prints that don't split or discolor quickly, also after numerous cleans.

The Direct to Film process begins with a digital style, which is published onto a PET (polyethylene terephthalate) movie making use of a specialized printer equipped with pigment inks. After printing, a layer of sticky powder is put on the damp ink. This powder binds the layout with each other, developing a transferable layer. Once cured under heat, the film is ready to be pressed onto the preferred surface utilizing a warm press. The movie is after that peeled off away, leaving a brilliant, professional-grade print.

What makes DTF attract attention is its capacity to collaborate with a wide variety of materials without the requirement for pre-treatment, a typical demand in other methods like DTG (Direct to Garment) printing. This flexibility, combined with its cost-effectiveness for small runs, has actually made DTF Transfers a game-changer in the personalized fashion industry.

The Advantages of Direct to Film Transfers.

When it involves Direct to Film Transfers, the advantages are numerous. Primarily, they use unequaled adaptability. Whether you're printing on T-shirts, hoodies, shoulder bag, or even non-fabric surfaces like timber or steel (with some testing), DTF delivers regular outcomes. This versatility opens up countless imaginative possibilities for entrepreneurs and musicians alike.

One more essential benefit is the top quality of the outcome. DTF Transfers produce sharp, vivid styles with no constraints on color gradients or detailed details. Unlike display printing, which needs separate displays for each shade and can be labor-intensive, Direct to Film enables photorealistic prints in a solitary pass. This effectiveness not only conserves time but additionally decreases arrangement expenses, making it an attractive choice for small-batch production or one-off custom-made orders.

Toughness is another feather in the cap of DTF. The prints are soft to the touch yet challenging enough to hold up against repeated cleaning and wear. This toughness ensures that your productions maintain their charm over time, keeping consumers satisfied and coming back for even more. Additionally, Direct to Film Transfers don't call for weeding-- a tedious step in vinyl-based approaches-- further simplifying the procedure.

For organizations, DTF Transfers also use a reduced barrier to entry. While the preliminary financial investment in a DTF printer, heat press, and materials might appear substantial, the lack of minimum order amounts and the capacity to publish on-demand make it an affordable option contrasted to contracting out or buying bulk screen printing equipment.

Exactly How UV DTF Transfers DTF Take It to the Next Level

While standard DTF Transfers have actually currently made waves, a more recent variant-- UV DTF Transfers-- is pushing the limits also additionally. UV DTF Transfers integrate the concepts of Direct to Film with ultraviolet (UV) healing modern technology, causing prints that are exceptionally durable and suitable for a broader variety of applications.

In the UV DTF process, UV-curable inks are printed onto a film, and a UV light immediately remedies the ink, locking it into place. This rapid healing boosts attachment and develops a print that's immune to scrapes, water, and UV light exposure. Once the design is cured, an adhesive layer is used, and the transfer prepares to be pressed onto the surface. The result is a shiny, responsive print that feels practically like a sticker but with premium long life.

Among the standout features of UV DTF Transfers is their ability to adhere to tough surface areas like glass, ceramic, plastic, and metal with ease. This makes them ideal for developing custom-made drinkware, phone situations, signage, and various other marketing things that surpass clothing. For example, imagine a streamlined, full-color logo on a stemless glass that will not fade or peel off, even after months of use-- that's the power of UV DTF.

Additionally, UV DTF Transfers use an increased, 3D-like result that includes a premium touch to the completed product. This appearance not only boosts the visual allure however also provides items an expert, high-end feeling that can command greater prices out there. For companies aiming to diversify their offerings or interest a specific niche target market, UV DTF Transfers offer an one-upmanship.

Getting Started with DTF and UV DTF Transfers

If you're interested by the possibilities of DTF and UV DTF Transfers, fortunately is that getting started is fairly uncomplicated. To begin with standard Direct to Film, you'll require a DTF printer (frequently a changed inkjet printer), PET movie, pigment inks, adhesive powder, a treating stove or heat source, and a warm press. Several providers use starter packages that bundle these fundamentals with each other, making it easier to dive in.

For UV DTF Transfers, the configuration is comparable yet requires a printer with UV-curable inks and a UV treating light. While the tools might set you back more upfront, the broadened variety of applications can promptly warrant the investment. Online tutorials, online forums, and maker assistance can also direct you with the understanding contour, guaranteeing you understand the process in no time at all.

When you've obtained your tools, the trick to success hinges on testing and technique. Test different substratums, fine-tune your warmth press setups, and improve your layouts to attain the most effective outcomes. Whether you're producing strong clothing graphics with DTF Transfers or appealing hard goods with UV DTF Transfers, interest to detail will set your job apart.

The Future of DTF Technology

As the need for customized, premium products continues to expand, DTF and UV DTF Transfers are positioned to play a considerable function in the future of printing. Their affordability, ease of use, and flexibility make them obtainable to a large audience, from small Etsy vendors to well established print shops. Additionally, continuous developments in ink solutions, movie high quality, and printer technology assurance to additionally enhance their capacities.

For eco conscious makers, it's worth keeping in mind that Direct to Film processes are coming to be much more lasting. Some makers are developing eco-friendly inks and recyclable movies, decreasing the eco-friendly footprint of this approach. As these developments unravel, DTF Transfers might come to be a much more attractive choice for the eco-minded business owner.

Final thought

In the world of customized printing, DTF Transfers and UV DTF Transfers stand for a powerful blend of creative thinking and innovation. Whether you're attracted to the versatility of Direct to Film for clothing or the durability of UV DTF for difficult surface areas, these techniques use endless chances to bring your concepts to life. By embracing DTF, you're not just embracing a printing approach-- you're joining a motion that's improving how we develop, create, and share personalized goods.

So, why wait? Dive into the globe of Direct to Film Transfers today and uncover how this innovative technique can boost your tasks, delight your customers, and unlock brand-new profits streams. The opportunities are as limitless as your creativity.

Houston DTF Transfers

9235 Colendale dr Houston TX 77037

8326660266

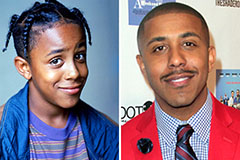

Ross Bagley Then & Now!

Ross Bagley Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!